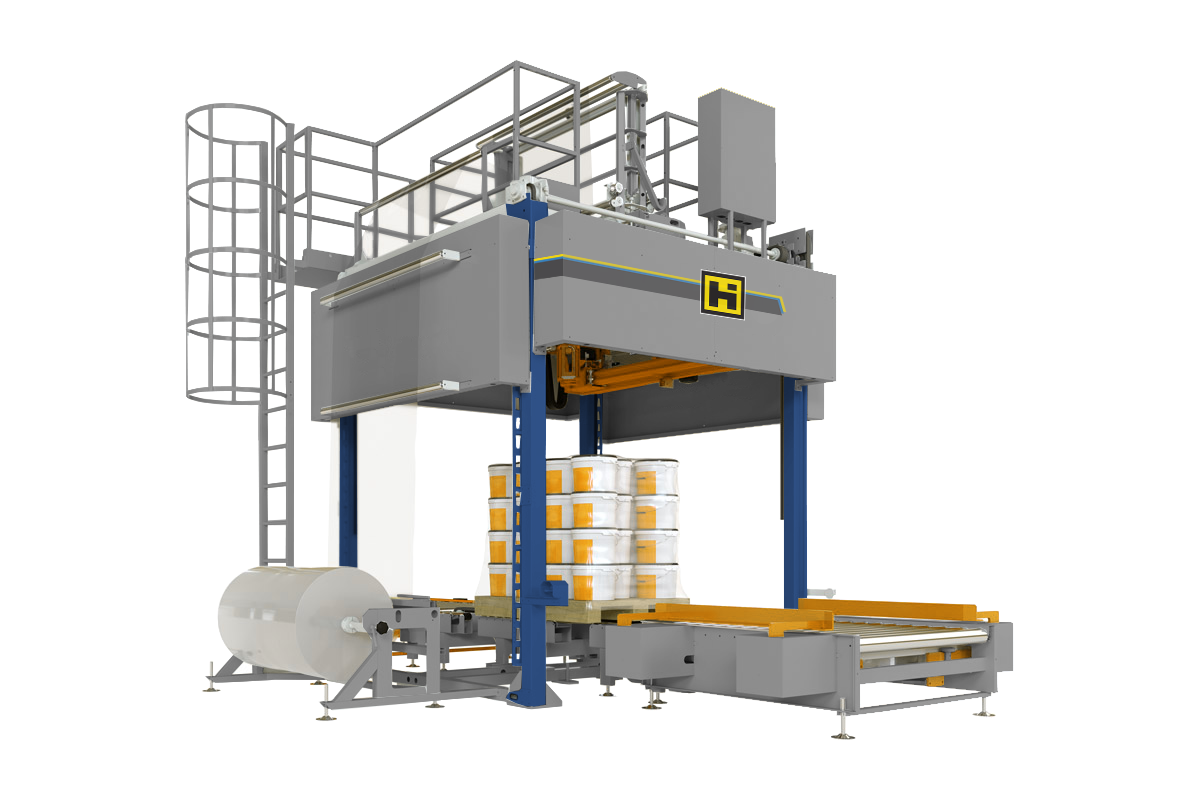

Handle-It’s Stretch Hooding equipment is a cutting-edge solution to enhance your products’ load stability and protection by using a tubular film that stretches to conform to the shape of the pallet.

Need help determining which one is right for you? Check out our comparison table.

The SH-FA-5000 is a reliable, entry-level stretch hooder that delivers versatile packaging for a wide range of pallet sizes. It’s available in four size configurations and can operate with up to three stretch film reels for unmatched flexibility.

The SH-FA-6000 is a high-performance stretch hooder designed for demanding production environments. With eight available models, it offers the widest packaging range and speeds of up to 280+ pallets per hour.

The SH-FA-7000 combines flexibility and simplicity, using a Cartesian film stretching system to accommodate various load sizes and shapes. It offers tailored packaging through an integrated dimension reader.

| SH-FA-5000 | SH-FA-6000 | SH-FA-7000 | |

|---|---|---|---|

| Production Capacity (depending on pallet size) | 70 Pallets per hour | 280 Pallets per hour | 80 Pallets per hour |

| Maximum Number of Reels | 3 | 6 | 2 |

| Minimum Dimensions (L x W) | 600 x 600 mm (23.62 x 23.62 in) | 500 x 400 mm (19.69 x 15.75 in) | 600 x 600 mm (23.62 x 23.62in) |

| Maximum Dimensions (L x W) | 2600 x 1400 mm (102.36 × 55.12 in) | 3600 x 2500 mm (141.73 × 98.43 in) | 2600 x 1400 mm (102.36 × 55.12 in) |

| Maximum Pallet Weight | 5500 lbs | 5500 lbs | 5500 lbs |

| Number of Size Formats | 4 | 9 | 4 |

Stretch hooders are only as effective as the film they run. The right film can make a noticeable difference in seal integrity, load stability, and overall efficiency.

While many customers source film independently, we provide film as a convenience for those who prefer a single point of support for their packaging system. We carry a curated selection of high-performance stretch hood films that are compatible with Handle-It machines and designed to deliver:

Many of our customers appreciate having a trusted partner who understands both the equipment and the materials that make them work best – especially during installation, startup testing, or film transition periods.

Need film recommendations? Talk to our experts about the right film for your product profile and machine setup.

Bottom border background color add here

Bottom border background color add here

Delve into our ‘FAQ’ section, where we address commonly asked questions and provide insightful answers about our Stretch Hooding Equipment. Your curiosity, our expertise.

Stretch hooders provide five-sided packaging that offers superior load stability and protection while using less material than traditional wrapping methods. They also eliminate film at the base of the pallet, making them ideal for facilities that use automated transport systems like AGVs.

Yes. The clear stretch film used in stretch hooding allows for excellent visibility, enabling easy barcode scanning and visual identification of products without removing or damaging the packaging.

Stretch hooders automate the hooding process and can wrap loads significantly faster than conventional stretch wrappers. This speeds up throughput, reduces manual labor, and boosts overall packaging line efficiency, especially when processing high volumes.

Didn’t see exactly what you were looking for? Let our experts help you find the equipment that’s perfect for your application and your budget.