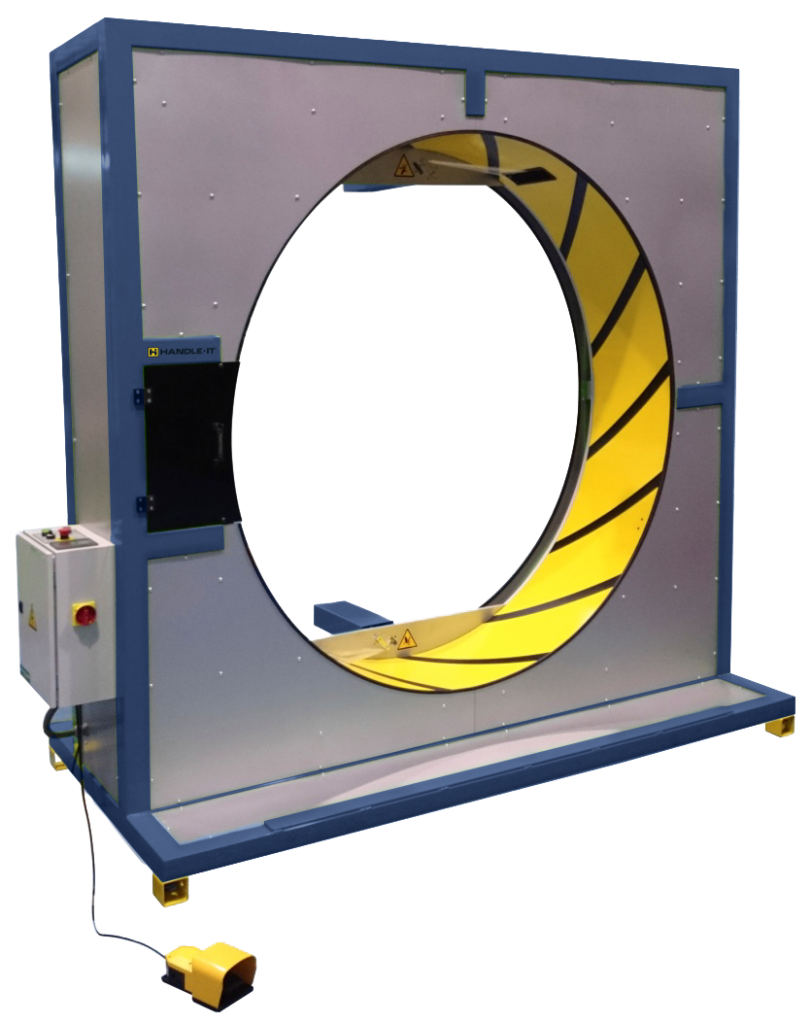

Handle-It offers various semi-automatic, automatic, and C-Style (C-Ringer) orbital wrapping machines. These horizontal bundle wrapping machines come in varying sizes and range from handling small to very large products. They are ideal for manufacturing and warehouse applications where loads must be grouped, wrapped, and protected.

Users can choose from three popular “ringer” designs depending on the application and desired automation level.

High-speed rotating ring mechanism powered by durable servo or variable frequency drives (VFDs).

All Orbitals come with dual film rolls, auto clamp and cut along with variable film tension control.

Intuitive controls and easily adjustable wrapping programs HMI screens with GIF video instructions.

Bottom border background color add here

Larger orbital wrappers allow you to handle a wide variety of package sizes. Smaller orbital wrapper units are portable, allowing them to be moved easily.

Integrate seamlessly into warehouse operations, featuring conveyor compatibility and advanced programmable controls.

With up to 180 RPM speeds, orbital wrappers increase productivity and reduce costs in high-volume warehouses.

Bottom border background color add here

Semi-automatic horizontal orbital wrappers are used for bundling products with some manual intervention. It is more efficient and cost-effective than your current manual wrapping process.

Automatic horizontal orbital wrappers are used for bundling products with no manual effort or operator. Reduces your labor costs and increases production capacity

Semi-automatic horizontal orbital wrappers are used for bundling round products and frames, windows, or doors without glass with some manual intervention. It is more efficient and cost-effective than your current manual wrapping process.

| Semi-Automatic Orbital Wrappers | Automatic Orbital Wrappers | C-Style Orbital Wrappers | |

|---|---|---|---|

| Operation | Manual loading, automated wrapping process | Fully automated, including loading, threading, and cutting | Semi-automatic, manual feeding of round or irregular products |

| Conveyor Integration | Standalone operation (no conveyor integration) | Integrated with conveyor systems for seamless operation | Standalone operation, designed for specific shapes (round or tubular) |

| Production Capacity | Moderate throughput, suitable for small to medium-scale operations | High throughput, ideal for large-scale packaging | Moderate capacity, optimized for specialized products |

| Maximum Product Dimensions | Varies by model, accommodating mid-sized products | Varies by model, handling larger products | Varies by model, suitable for round or tubular items |

| Accessories | Foot pedal for activation, adjustable settings | Touchscreen interfaces, advanced programmable options | Safety footswitch, toothed belt drive system |

| Film Delivery System | Single or dual film reel options | Dual film reels for faster wrapping | Dual film reels for reinforced wrapping |

| Control Features | Adjustable tension, speed controls | Advanced controls with customizable programs | Adjustable film tension and rotation speed |

| Safety Features | Basic safety features like emergency stops | Enhanced safety features with automatic cut-off | Safety-focused design for operator protection |

Yes. Our orbital wrappers require both air and electrical power. Power requirements vary by model size—smaller machines may use 110V single-phase, while larger models require up to 480V three-phase.

Yes. We offer fully integrated systems and can provide the necessary conveyors for automatic configurations.

Our machines are designed with a smaller footprint than many competing models, making them ideal for facilities where space is limited.

Handle-It® orbital wrappers feature enclosed designs that prevent dust, debris, and accidental contact with moving parts—helping reduce maintenance needs and improve operator safety.

Standard models use two film rolls, which is more than most competitors. This dual-roll system increases efficiency and reduces the frequency of refills.

Yes. All Handle-It® orbital wrapper models include auto clamp and cut as a standard feature.

We offer orbital wrappers with ring sizes ranging from 19 inches to 98 inches, covering a wide range of product dimensions.

Yes. Each ring size is available in both semi-automatic and fully automatic models. We also offer C-style ring orbital machines for specialized applications.

Our machines use film with a 1.5” core, which allows for more footage per roll and reduces downtime for film changes. They can also be converted to accommodate 3” core rolls, offering flexibility for different film types.

Didn’t see exactly what you were looking for? Let our experts help you find the equipment that’s perfect for your application and your budget.