Automatic Stretch Wrap Machines

Automate your pallet wrapping process with Handle It’s innovative range of fully automatic stretch wrap machines. Our cost-effective solutions reduce labor costs, fuel productivity, and improve your bottom line. They ensure streamlined operations by minimizing injury risks and freeing up your workforce for more crucial tasks.

Handle It stretch wrappers provide superior load containment, resulting in fewer lost or damaged products during transit and improved customer satisfaction. Whether you need conveyor-fed, portable units, turntable, or rotary arm styles, we’ve got you covered.

Discover the perfect fit for your operations in our extensive lineup below and compare models to find the one that’s right for your needs.

Showing all 9 results

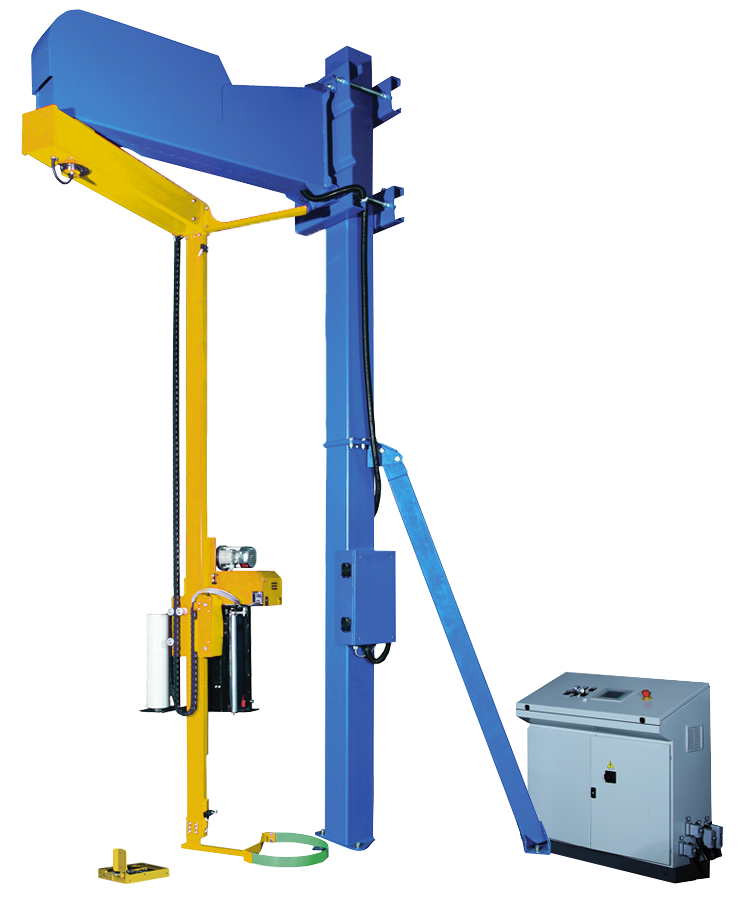

1100AA-C Automatic Stretch Wrap Machine

RA 2200 AAC Automatic Rotary Arm Pallet Wrapper

RA 2300 AAC Automatic Rotary Arm Pallet Wrapper

FA 4000 Automatic Conveyor Pallet Wrapper

FA 4100 TURNTABLE AUTOMATIC PALLET WRAPPER

FA 4200 Automatic Conveyor Rotary Arm Pallet Wrapper

FA 4300 Automatic Conveyor Rotary Arm Pallet Wrapper

FA 4400 AUTOMATIC ROTARY TOWER PALLET WRAPPER

FA 4500 Automatic Conveyor Rotary Arm Pallet Wrapper

Explore the Benefits of our Automated Solutions

Reduced Labor Costs

Our automatic pallet wrappers cut labor costs by streamlining operations and reducing the number of operators needed to wrap each load efficiently.

Increased Production

Step up to higher production rates without compromising on quality. Enjoy consistently precise wraps in a reliable process that bolsters throughput.

Decreased Injury Risks

Handle It automatic stretch wrappers allow drivers to remain on their forklifts, reducing body strain and safety risks associated with being physically close to the wrapping machine.

Handle It’s Automatic Stretch Wrap Machine Options

Handle It has an automatic stretch wrap machine for every budget and application, from entry-level to heavy use. Explore our models below to learn more and find the machine that meets your packing needs.

The Handle It Automatic Stretch Wrapper Advantage:

- Designed and manufactured in Europe

- Final assembly, testing, and programming in Milwaukee, Wi

- ISO 9000 certification

- CE compliant

- Utilize high-quality components

- We test and pre-program every machine before shipment

| Model #: |

|---|

| Max Average Loads |

| Type |

| Load Capacity |

| Power requirement |

| Air supply (film sealing unit) |

| Max Pallet Size |

| Machine Dimensions (L x W x H) |

| Pneumatic Sealing Unit (Film clamp, cut, & hot weld film tail) |

| Electronic Film Tension Control |

| Power Pre-Stretch 250% |

| Variable Power Pre-Stretch (600%) |

| Carriage Drive system |

| Standard maximum wrap height |

| Extended Mast Wrap Height |

| Custom Top & Bottom Wraps |

| Integrated Scale |

| Onboard Diagnostics |

| Total Pallets Wrapped counter |

| # Of User Saved Cycle Programs |

| Standard PLC |

| Remote connection via Ethernet |

| Model #: | 1100 AA-C | 2200 AAC | 2300 AAC | FA 4000 | FA 4100 | FA 4200 | FA 4300 | FA 4400 | FA 4500 |

|---|---|---|---|---|---|---|---|---|---|

| Max Average Loads | 300 per day | 300 per day | 30 per hour | 30 per hour | 40 per hour | 30 per hour | 40 per hour | 50 per hour | 100+ per hour |

| Type | Portable Turntable | Rotary Arm | Rotary Arm | Conveyor Turntable | Conveyor Turntable | Conveyor Rotary Arm | Conveyor Rotary Arm | Conveyor Rotary Arm | Conveyor Rotary Arm |

| Load Capacity | 4400lb | Unlimited | Unlimited | 3800lb | 3800lb | Conveyor Determined | Conveyor Determined | 3800lb | Conveyor Determined |

| Power requirement | 110v | 110v | 110v | 480 3ph. | 480 3ph. | 480 3ph. | 480 3ph. | 480 3ph. | 480 3ph. |

| Air supply (film sealing unit) | 90 psi | 90 psi | 90 psi | 90 psi | 90 psi | 90 psi | |||

| Max Pallet Size | (93” Diagonal) | Customizable | Customizable | Customizable | Customizable | Customizable | Customizable | Customizable | Customizable |

| Machine Dimensions (L x W x H) | 113″ L x 70″ W x 97″ H | 125” L x 113” W x 140” H | 125” L x 113” W x 140” H | 113″ L x 70″ W x 97″ H | 113” L x 70” W x 101” H | 155” L x 142” W x 135” H | |||

| Pneumatic Sealing Unit (Film clamp, cut, & hot weld film tail) | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Electronic Film Tension Control | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Power Pre-Stretch 250% | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Variable Power Pre-Stretch (600%) | Optional | Optional | Optional | Optional | Optional | Optional | Optional | Optional | Optional |

| Carriage Drive system | Rack and Pinion | Belt | Belt | Belt | Belt | Belt | Belt | Belt | Belt |

| Standard maximum wrap height | 94″ | 94″ | 94″ | 86″ | 86″ | 95″ | 95″ | 86″ | 95″ |

| Extended Mast Wrap Height | 118” | 118” | 118” | Customizable | Customizable | Customizable | Customizable | Customizable | Customizable |

| Custom Top & Bottom Wraps | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Integrated Scale | Optional | Optional | Optional | Optional | Optional | Optional | Optional | Optional | Optional |

| Onboard Diagnostics | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

| Total Pallets Wrapped counter | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| # Of User Saved Cycle Programs | 32 | 32 | 32 | 10 | 10 | 10 | 10 | 10 | 10 |

| Standard PLC | Siemens | Siemens | Siemens | Siemens | Siemens | Siemens | |||

| Remote connection via Ethernet | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ |

What Are Automatic Stretch Wrap Machines?

Automatic stretch wrap machines automate the pallet wrapping process while reducing labor, boosting efficiency, and saving time. Many available models cater to everything from handling heavy, unstable loads to meeting the demands of high-volume, fast-paced operations. Each model offers unique features and advantages, allowing for a tailored approach to your pallet wrapping process.

How Do Automatic Pallet Wrapper Machines Work?

Automatic pallet wrapper machines efficiently automate the entire pallet wrapping process. These machines typically employ advanced technology, including rotating arms or turntables, to securely wrap the stretch film around the palletized load. The process begins with placing the pallet onto the machine's platform or conveyor system.

Once initiated, the machine automatically applies the stretch film around the load, ensuring optimal tension and containment. Some models offer customizable settings to adjust the number of revolutions or the film tension based on specific load requirements. The result is a tightly wrapped pallet ready for safe transport and storage.

Semi-Automatic vs. Automatic Wrapping Machines

Automatic and semi-automatic stretch wrappers differ primarily in the extent of automation they provide for the wrapping process. This means that with an automatic wrapper, your job is easier and faster, while a semi-automatic wrapper requires more human involvement.

Semi-automatic wrapping machines require the user to attach the film and activate the wrapping cycle manually. Although they generally have a lower throughput, semi-automatic wrappers are suitable for smaller businesses or those with variable production volumes. These machines offer a significant improvement in efficiency and time savings compared to wrapping pallets manually.

Fully automated pallet wrappers eliminate the need for manual film attachment and further streamline the wrapping process. For example, if you wrap 300 pallets daily with a semi-automatic machine, the driver must get off the forklift 300 times to apply the film, hit start, and wait for the pallet to wrap (about 1 minute). They would then need to hop back on the forklift to remove the pallet, then go pick up and deliver another one.

Fully automatic stretch wrap machines can also incorporate conveyor systems that automatically load and unload pallets and utilize advanced control systems to manage the entire wrapping process. These automated pallet wrapping systems can handle large numbers of loads per hour, making them ideal for businesses with high throughput requirements.

Applications

Handle It automatic stretch wrappers are ideal for a wide range of applications, including boxes, bags and sacks.

Boxes— The adjustable settings enable precise control over tension and wrapping patterns, ensuring a tailored solution for different box sizes and shapes. These machines minimize the risk of product damage during transportation, safeguarding your goods throughout the supply chain.

Bags and sacks— Effectively secure bags and sacks of different sizes, whether they contain loose items, powders, or other materials. Automation eliminates manual handling and ensures precise and tight wrapping, minimizing the risk of tampering or damage.