Refrigerated Products

Hand wrapping pallets of refrigerated products can lead to damage, bruises, and spoilage during transport or storage. A pallet wrapping machine from Handle-It will provide a cleaner, more consistent, and secure wrap.

Handle-It pallet wrapping machines come with a wide range of useful features, such as:

- User-friendly control panel

- Ability to use perforated shrink wrap

- Cold kit for the machine

- 250% power pre-stretch to save shrink wrap

- Rack and pinion carriage drive for increased reliability

- Up to 32 custom wrap cycles

Recommended Products

850PS Semi-Auto Stretch Wrap Machine

The Model 850PS comes with a 250% power pre-stretch feature which will help save on shrink wrap costs. Ideal for operations that wrap up to 100 pallets per day.

LEARN MORE

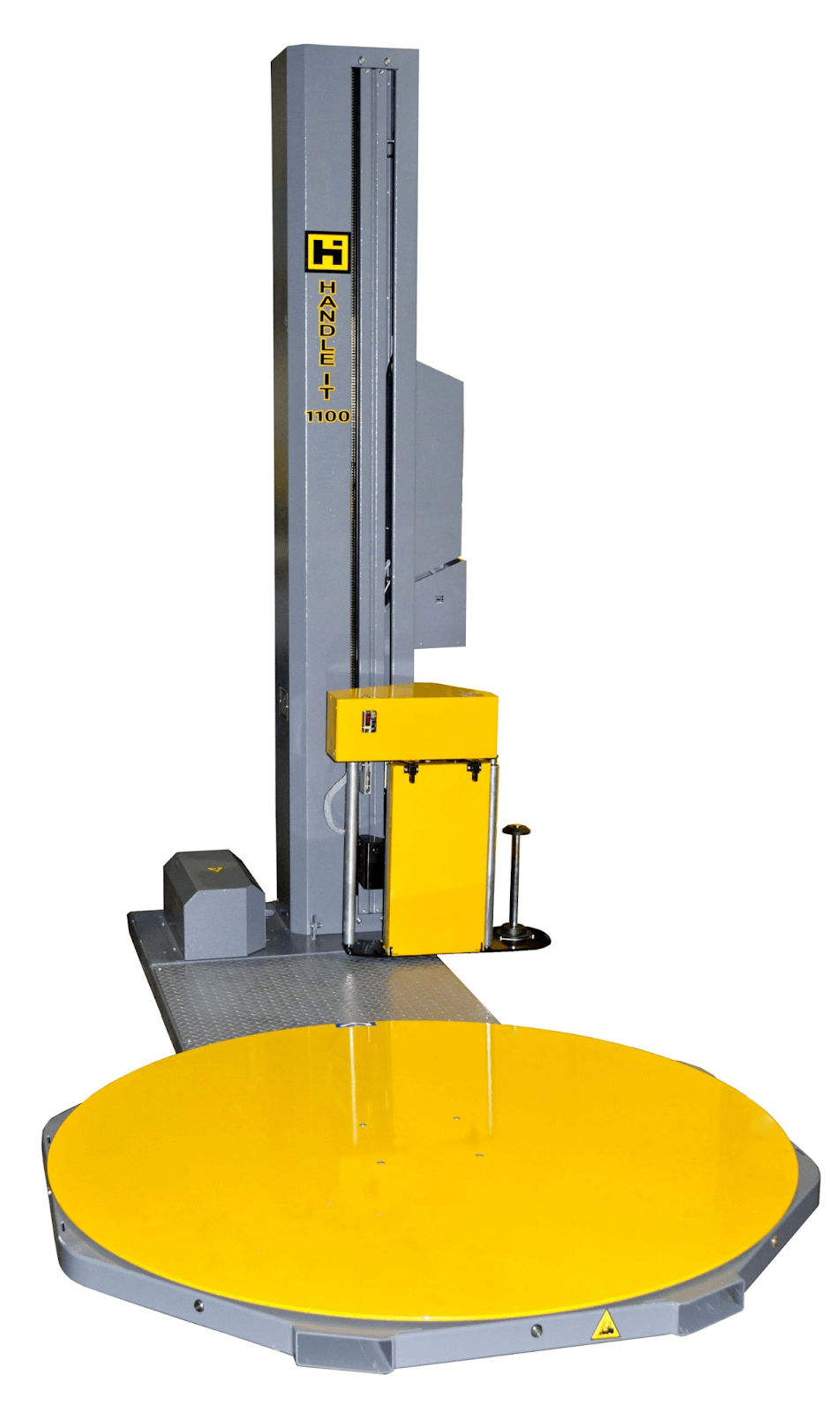

1100 Semi-Auto Turntable Stretch Wrap Machine

Wrap up to 300 pallets per day with the Model 1100 semi-automatic stretch wrapper. Thirty-two end-user programs, 250% film pre-stretch, and a 4,400lb max load capacity will help your operation run efficiently.

LEARN MORE

1100AA-C Automatic Stretch Wrap Machine

The Model 1100AA-C fully automatic pallet wrapper will allow workers to operate the machine while sitting on their forklift. Ideal for operations that need to wrap up to 300 loads per day.

LEARN MOREOversized Pallets Packaging Pro Tips

We offer two levels of cold kits for our machines—freezing and just below freezing. Kit features include:

- Heater for the control panel to keep it warm.

- Low-temperature oil for gearboxes.

- Cabling and plastics are softer and more flexible (to avoid cracking).

- Support casters for the turntable are softer (to avoid cracking)

In cold environments, the stretch film can become static—we offer an anti-static brush that can reduce or eliminate the static.

Here are a few other pro-tips for stretch wrapping refrigerated products:

- Start with a 50% film tension for most loads using two or three top and bottom rotations.

- Start with less tension and slower speeds for cycle time and load containment. Gradually increase to optimize.

- Use a thicker film or lower tension when wrapping products with sharp edges.

- Increase the overwrap delay (“flanging time”) and top rotations for outlier products at the top.

- Try using a fixed height setting or increase the flanging time (Model 1100) for voids or empty spaces.

- Lock in with roping divide and set reinforcement extra height.

- Use variable tension to start with a lower tension at the pallet bottom. Gradually increase tension on the way down for a more secure load.

Explore Related Industries

The industries below can benefit from the many features of a Handle-It mobile or semi-automatic stretch wrapping machine.

Helpful Resources

Have Questions?

Explore News & Articles

Trust Handle-It for Efficient and Cost-Effective Packaging Solutions for Refrigerated Products

Contact our experts today to discover the perfect solution for your operation!