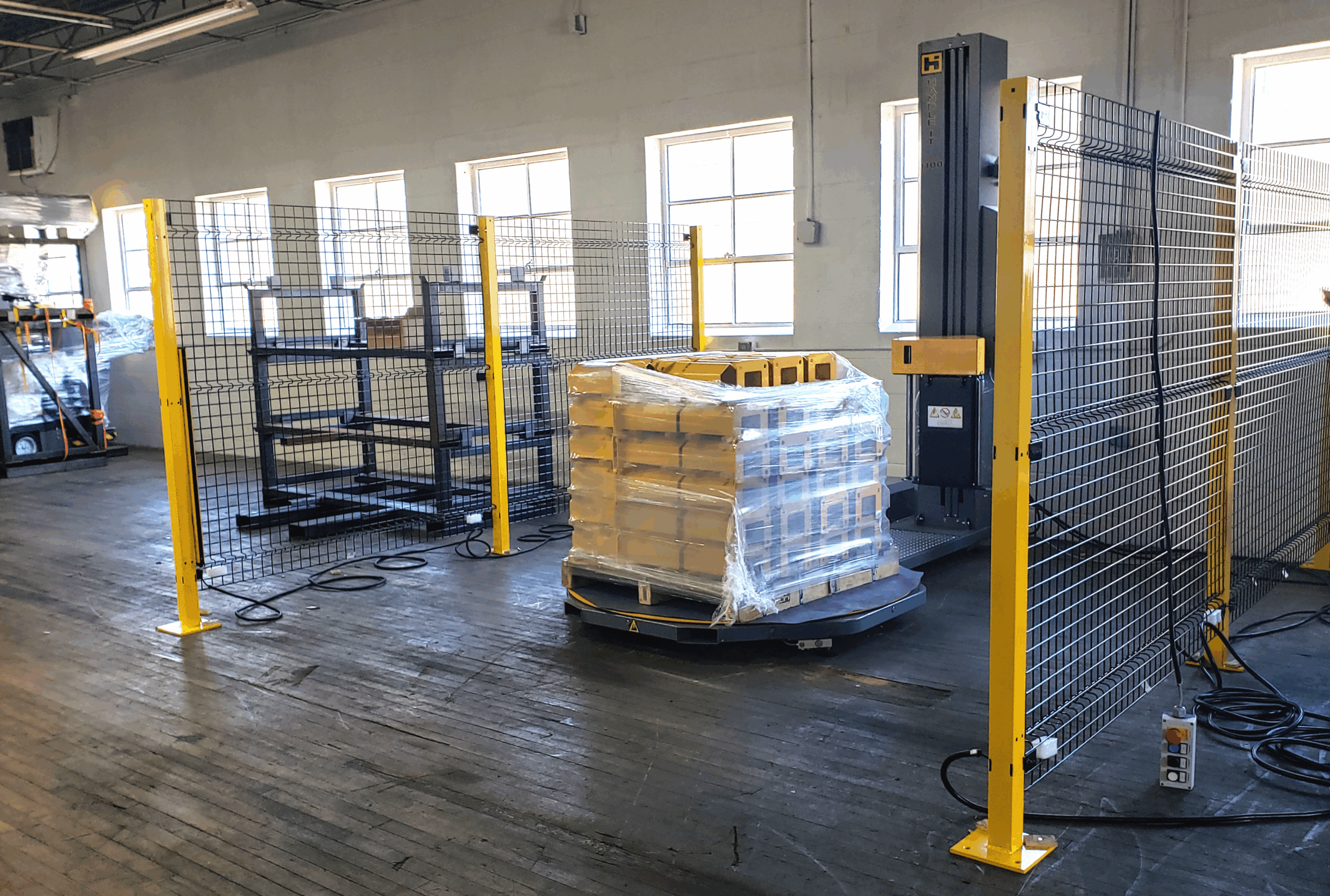

The Handle-It® Model 1100AA-C is a fully automatic stretch wrap machine designed to streamline end-of-line packaging operations. With automatic film attach, cut, and hot weld features, the 1100AA-C eliminates the need for operator intervention during wrapping, making it ideal for high-throughput environments.

Built on the proven 1100 platform, this model includes 250% powered film pre-stretch, customizable wrap settings, and a user-friendly touchscreen interface. It’s perfect for facilities looking to boost productivity and reduce labor costs without sacrificing wrapping consistency.

Stay on the forklift and start our automatic wrapper with remote control.

No need for manual film attachment or removal – operators only need to load and unload pallets.

250% powered pre-stretch minimizes film use and maximizes load containment.

Download the Printable Product Information Sheet (PDF)

Available Options:

Didn’t see exactly what you were looking for? Let our experts help you find the equipment that’s perfect for your application and your budget.