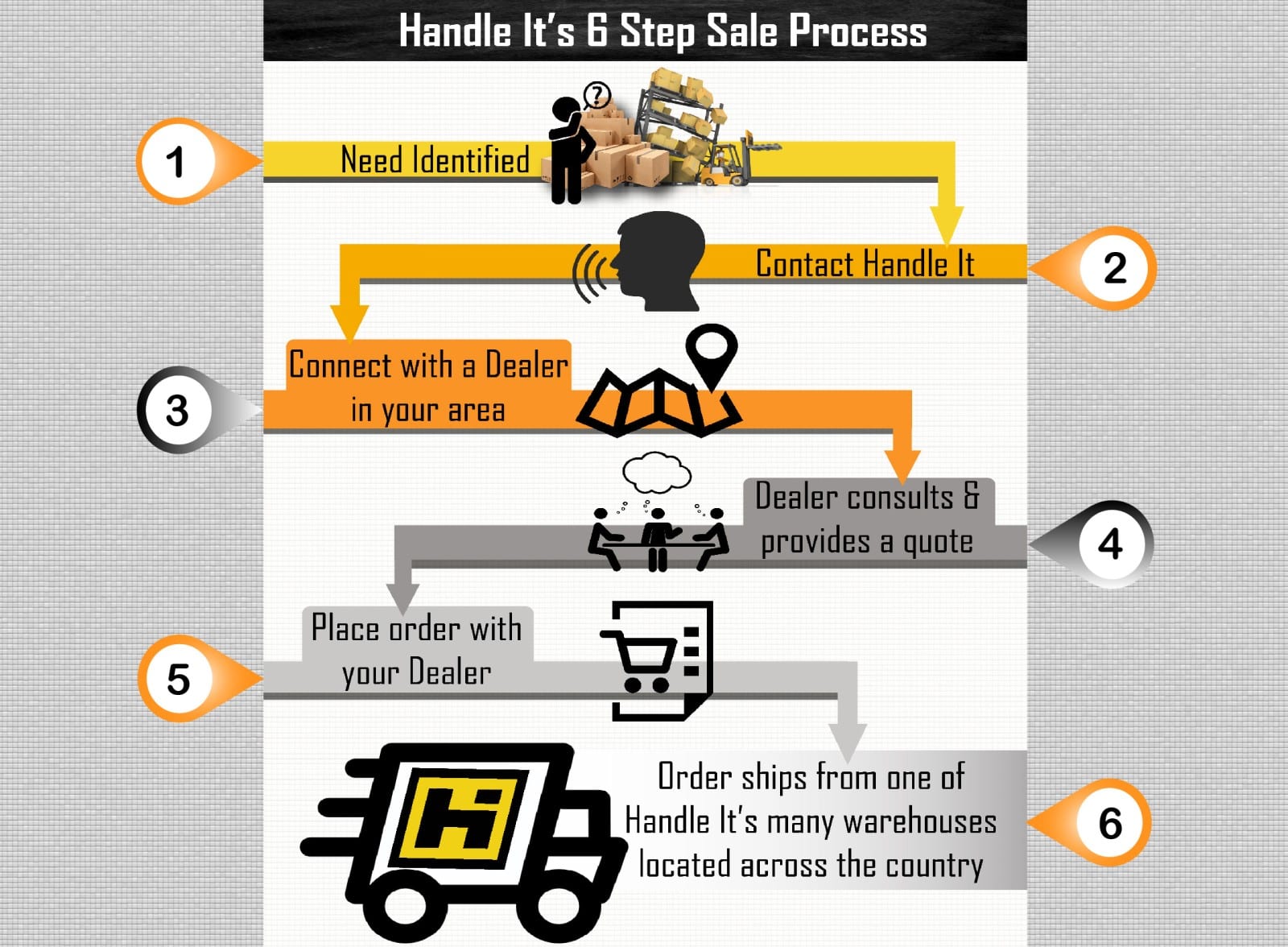

At Handle It, we strive to supply our industrial customers with our high-quality and durable impact protection products and stretch wrap machines. We sell through a nationwide network of independent dealers to serve our customers as effectively as possible.

Some of these dealers you may already work with daily. We have dealers across the state of Vermont covering major cities, including

- Burlington

- Essex

- South Burlington

- Colchester

- Rutland city

- Bennington

- Brattleboro

- Hartford

- Essex Junction

- Milton

If you have a preferred dealer you already work with, let us know as we may work with them as well.

Request a quote, let us know your location, and one of our sales consultants will help you select the right equipment that meets your business needs.

We will then get a nearby dealer to provide you with a quote. The types of dealers we sell through are typically forklift, material handling, packaging equipment, system integrators, and various industrial suppliers/dealers. We can work with your preferred dealer if they are a dealer of ours and can provide a quote through them. Or, we will choose the best dealer in your area to provide you a quote. Our dealers also offer installation and after-sale support services. If you need installation, please note that in your quote request.

Handle It Dealer Network

Packaging Equipment Pre-Sale and Post-Sale Services & Dealer Support

| Pre-Sale & During Sale Support | Post-Sale Support |

|---|---|

|

|

|

|

|

|

|

|

|

|

Guard Rail Pre-Sale and Post-Sale Services & Dealer Support

| Pre-Sale and During Sale Services | Post-Sale Services and Dealer Support |

|---|---|

|

|

|

|

Pallet Wrapper Pre-Sale and Post-Sale Services & Dealer Support

| Pre-Sale & During Sale Support |

|

|

|

|

|

| Post-Sale Support |

|

|

|

|

|

Guard Rail Pre-Sale and Post-Sale Services & Dealer Support

| Pre-Sale and During Sale Services |

|

|

| Post-Sale Services and Dealer Support |

|

|

Are you interested in joining Handle It’s network of dealers? Submit your information.

Pallet Wrapping Machines

Handle It offers a wide variety of fully-automatic, semi-automatic, and mobile pallet wrapping machines and stretch wrappers. Our products range from entry-level equipment to heavy-duty machinery.

- Semi-automatic: We offer entry-level, mid-level, higher-level, and heavy-duty machines depending on your load.

- Automatic: It allows you to control the machine via remote control, so you don’t have to get off your forklift for any part of the wrap cycle. This improves your efficiency and overall productivity. The machine will automatically attach, hot seal, and cut the film.

- Mobile: Niche machine that can wrap very long or heavy pallets and be stowed away when not in use.

- Rotary Arm: Ideal for very heavy or unstable pallets. Can wrap up to 300 loads per day.

- Pallet Wrapper Accessories: Various accessories to increase efficiency, ease of use, loading method and oversize pallet options, load containment, and environmental and safety options.

Guard Rails & Rack Protectors

Our Guard Rails, Rack Protectors, and Safety Barriers are designed with our customers in mind. Protect your workers, products, and investments with our high-quality and durable products. All of our protective guards can withstand damage due to forklift impact.

Our guard rail and rack protectors include:

We work with some of the best dealers in the country for:

- Installing guard rails

- Installation

- Onsite consulting

- After-sales service

- Safety audits

- Permitting & engineering

About Handle It, Inc.

Since 1999, Handle It has lived by our mission to provide high-quality industrial and warehouse solutions to serve the needs of our customers. Our focus on customer service, utilizing quick response, superior products, and competition has been our driving force since the beginning. We provide an environment that promotes opportunity, mutual respect, and integrity for all the people we are invested in and those who are invested in us.

Handle It Has a Model That’s Right For You

A model for every application. A model for every budget. We manufacture floor mounted safety equipment, dock equipment, ergonomic equipment, packaging equipment and other material handling products to satisfy our industrial customer’s requirements. With clients both nationally and internationally, we have what you need.