The 800 and 850PS semi-auto stretch wrap machines offer a wide range of benefits that provide superior functionality, efficiency, and flexibility when it comes to wrapping your pallets. The user-friendly control panel will enable your workers to wrap an average of 100 max loads per day.

An automatic or manual cycle provides for the creation of 18 customizable wrap programs that users can save for future use. The recordable program feature allows for up to 99 pre-programmed steps in a single cycle, thereby making it highly customizable for any pallet wrap situation.

Both machines share the same specifications and similar performance:

| Model # | 800 | 850PS |

|---|---|---|

| Load Capacity | 4400lbs | 4400lbs |

| Max Average Loads Per Day | 100 | 100 |

| Machine Dimensions | 93”x 59”x 88” | 93”x 59”x 88” |

| Max Wrap Height | 86” | 86” |

| Extended Mast Wrap Height | 98” | 98” |

| # Of Cycle Parameters | 6 | 6 |

| # Of User Saved Cycle Programs | 9 regular & 9 recordable | |

| Photo Eye | Yes | Yes |

| Electronic Film Tension Control | Yes | Yes |

| Custom Top & Bottom Wraps | Yes | Yes |

| Rack & Pinion Carriage Drive | Yes | Yes |

| Power Pre-Stretch | Not Available | 250% |

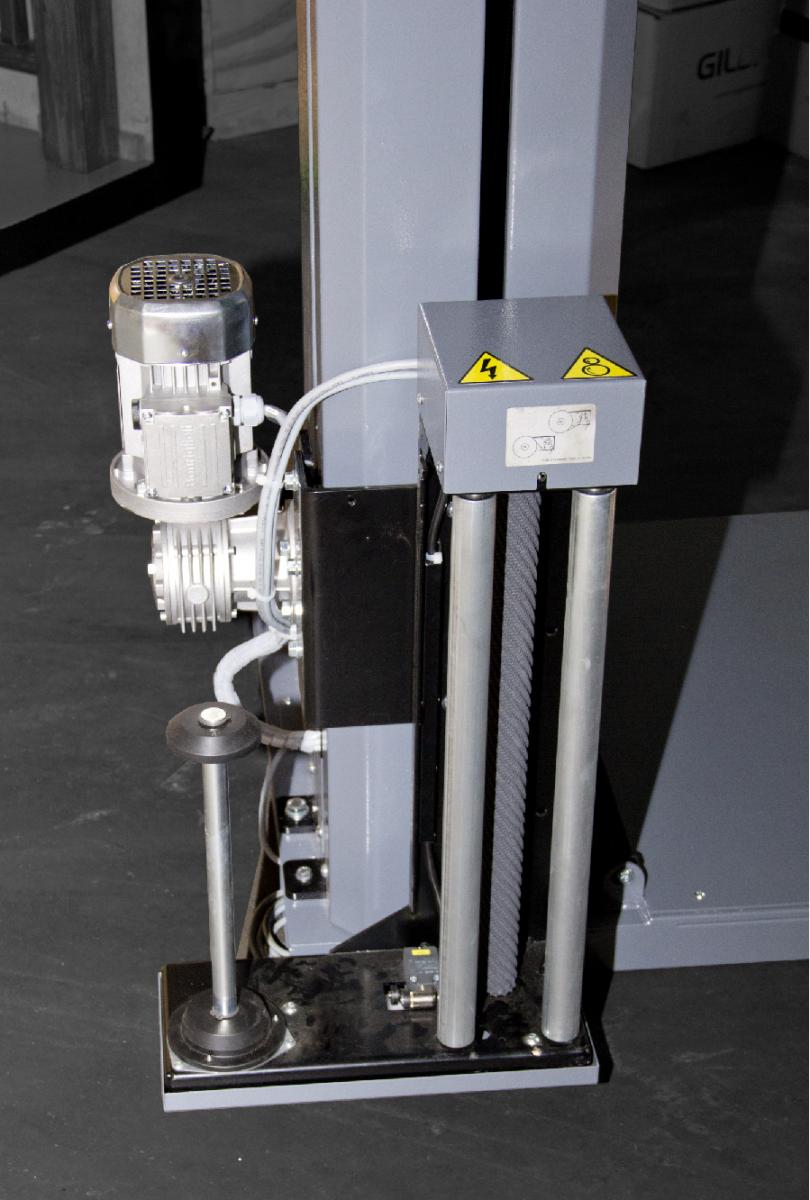

The main difference between the two machines is the ability of the 850PS to perform a 250% Power Pre-Stretch. This means that it uses up to 60% less stretch wrap than the 800 model. That translates to substantial cost savings over a short period of time.

The 850PS Model uses electrically-controlled rollers that stretch the film up to 250% before leaving the carriage. This helps lower the overall cost of packaging and increases film efficiency.

The below table shows the approximate film savings per year and the ROI of the 850PS power pre-stretch carriage unit. As you can see, the savings quickly add up and justify the price difference from the 800 model.

| 850PS ROI vs. 800 (non pre-stretch machine) | ||||

| Film Roll Length & Avg. Cost | Pallets Wrapped Per Day | Film Savings Per Year |

Payoff on the machine | Payoff power pre-stretch upgrade cost (months) |

| 5000’ @ $57.00 per roll | 20 | $5,200 | 19 | 6 months |

| 30 | $7,800 | 13 | 4 months | |

| 50 | $13,000 | 7 | 2 months | |

| 100 | $26,000 | 4 | 1 month | |

The Handle It® 800 and 850PS semi-auto pallet wrap machines offer top-of-the-line functionality and will help improve efficiencies and streamline your packaging processes. They’re an ideal choice if you’re looking for an efficient stretch wrap machine that’s capable of wrapping medium-to-high volumes of pallets every day.

Contact one of our experts to learn more.

BACK

Shop our wide variety of pallet wrapping machines and stretch wrappers to improve your current packaging process.

Shop our several types and sizes of orbital wrapping machines to meet your horizontal product bundling needs.

Shop our pallet strapping equipment to secure your products for safe and reliable transport.

Shop our guard rail systems and components to improve the safety of the people, structures and items in your warehouse.

Shop rack & post protectors to decrease the damage to your pallet racks and posts due to impact from forklifts and pallets.